High hardness and wear resistance: Brown fused alumina has a relatively high Mohs hardness 9, which enables it to quickly grind and polish hard alloys and other high-hardness materials. At the same time, it has strong wear resistance, and the particles do not wear easily during the spraying process, allowing for long-term stable cutting performance.

Excellent thermal and chemical stability: Brown fused alumina can maintain its physical and chemical properties stably at high temperatures, making it suitable for processing materials such as high-temperature alloys; its chemical properties are stable, resistant to acid and alkali corrosion, and will not undergo chemical reactions with hard alloys, ensuring the reliability of the processing results.

Sharpness and toughness: Under the action of pressure, the brown corundum particles will continuously fracture to form new sharp cutting edges, avoiding dulling and ensuring rapid cutting during continuous grinding; at the same time, its internal micro-crack structure can absorb impact energy, reducing damage to the workpiece.

Wide applicability: The hardness and toughness of brown corundum are moderate, which can effectively remove the oxide layer, burrs and scratches on the surface of hard alloys, while achieving smooth processing and improving processing efficiency.

Description:

Brown fused alumina is produced by melting high-quality bauxite, iron filings, and anthracite in an electric arc furnace at high temperatures 2200℃. The material is then crushed, shaped in a self-grinding machine, iron is removed by magnetic separation, and it is screened into various sizes. The main chemical component is Al2O3, with a content of 94%-96%, along with small amounts of Fe, Si, and Ti. It has a dense texture, high hardness, and is brown in color with great toughness.It is suitable for manufacturing ceramic and resin high-bond abrasives, as well as for grinding, polishing, sandblasting, precision casting, and refractory materials.

Production procedure:

Typical physical properties for brown fused alumina:

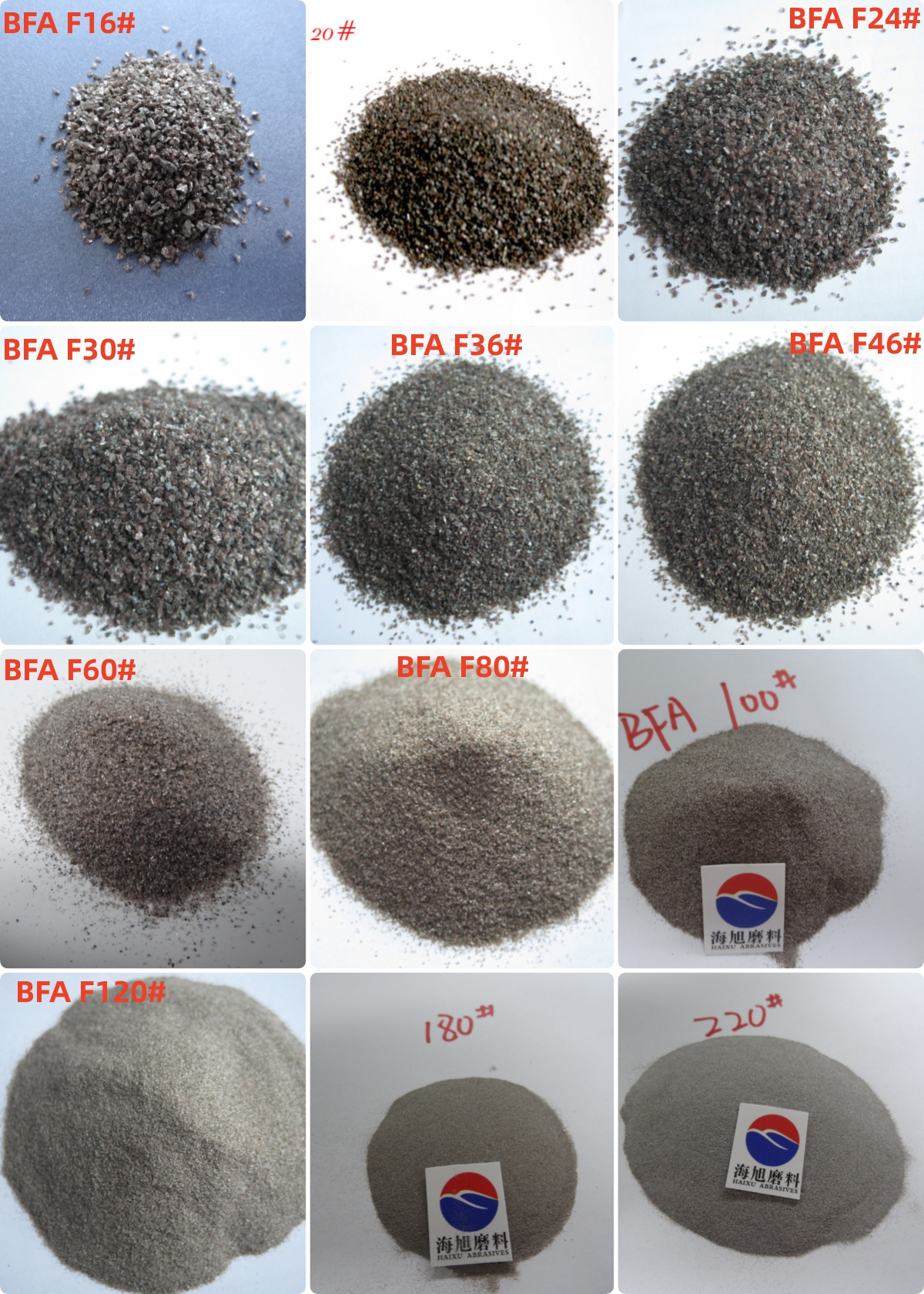

型号Available sizes: | F8, F10, F12, F14, F16, F20, F22, F24, F30, F36, F40, F46, F54, F60, F70, F80, F90, F100, F120, F150, F180, F220# | |||||

chemcial data | ||||||

型号Size | Al2O3 | TiO2 | Fe2O3 | SiO2 | ||

F24# | ≥95% | ≤3% | ≤0.5% | ≤1.5% | ||

physical data | ||||||

堆积密度(Bulk density) | 体积密度(Specific Gravity) | 莫氏硬度(Mohs Hardness) | ||||

1.75-1.95g/cm3 | 3.6-3.9g/cm3 min | 9 | ||||

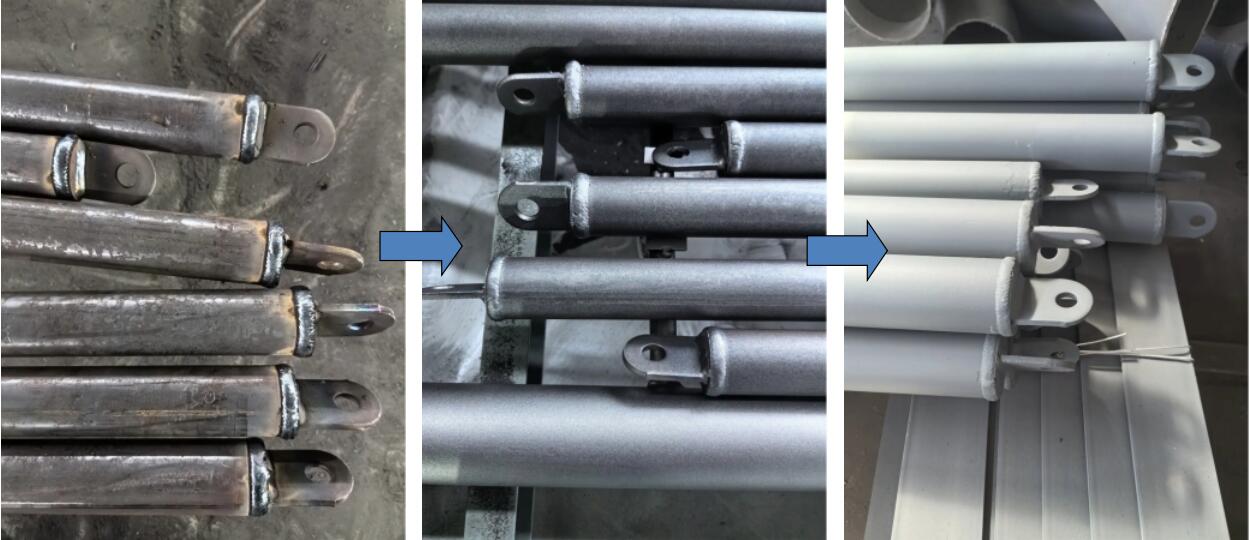

Before and after sand blasting comparison picture: