Tilting furnace brown fused alumina

Brown fused alumina can be divided into two kinds from the smelting method: tilting furnace smelting brown fused alumina and fixed furnace smelting brown fused alumina.

Tilting furnace: The process of producing brown fused alumina in the tilting furnace is continuous (in layman’s terms, it is smelting while flowing out and then cooling), with a high degree of mechanization and reasonable heat utilization. After the smelting in the tilting furnace is completed, the melt is poured into the mold for cooling and forming. This method makes the production efficiency higher, the unit power consumption is lower, and the cost is lower.

Fixed furnace: The fixed furnace is turned off and cooled after the smelting is completed. The production process is not continuous, the degree of mechanization is low, and the thermal energy utilization rate is low. The fixed furnace needs to be reheated before it can continue production, resulting in high energy consumption and low production efficiency. Simply put, the tilting furnace is smelted while pouring out and cooling, while the fixed furnace is used directly after the fire is turned off, and it is reheated when smelting is needed.

So what is the difference between brown corundum smelted by these two different methods?

Different product quality :

Tilting furnace brown fused alumina: produced by the tilting furnace has less silicon content, small crystal size, more combined bodies, and high glass phase. It has good self-sharpening and good density, but poor toughness and greater brittleness. Therefore, brown corundum from the tilting furnace is mostly used in consolidated abrasives and refractory materials.

Fixed furnace brown fused alumina: produced by the fixed furnace has large crystal volume, few combined bodies, and less glass phase. It has high hardness, good wear resistance, good toughness, but poor thermal stability. Therefore, fixed furnace brown corundum is mostly used in abrasive tool making.

Application fields

Tilting furnace brown fused alumina: Due to its good self-sharpening and high density, it is often used in polishing, sandblasting, precision casting, refractory materials and other fields. It also performs well in the fields of manufacturing grinding wheels, oilstones, emery cloths, sandpapers, etc. that require brown corundum sand as raw materials.

Fixed furnace brown fused alumina: Due to its high hardness and good wear resistance, it is often used in the production of abrasive tools.

Energy saving effect

Tilting furnace: Due to continuous production, the heat energy utilization rate is high and the energy saving effect is good.

Fixed furnace: Due to discontinuous production, the heat energy utilization rate is low and the energy consumption is high.

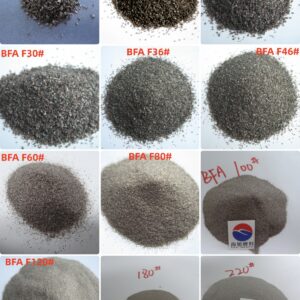

Data for brown fused alumina:

AL2O3 | ≥95% | Moh’s hardness | 9.0 |

Sio2 | ≤1.5% | Bulk density | 1.53-1.99g/cm³ |

Fe2O3 | ≤0.5% | Real density | 3.6-3.9/cm³ |

TiO2 | ≤3% | Melting point | 2250℃ |

The maximum temperature | 1900℃ |