Mn steel sandblasting by brown corundum

Brown corundum can be used for sandblasting of manganese Mn steel. Brown fused alumina has high hardness, high wear resistance and chemical stability, which make it perform well in sandblasting. Its hardness is as high as 9, second only to diamond, which enables it to maintain its shape and stability during sandblasting and effectively remove stains and oxide layers on the surface. In addition, it also has good wear resistance and can maintain good grinding performance during long-term use, reduce the frequency of changing grinding materials, improve work efficiency and reduce costs.

Brown corundum also has the characteristics of high specific gravity and low dust, which helps to reduce environmental pollution and protect the health of operators. Its good toughness makes the sandblasting process more uniform and consistent, improving the predictability and reliability of the treatment effect. In addition, sandblasting with brown fused alumina can remove pollutants such as soluble salts on the surface, making the surface cleaner and smoother, and improving the corrosion resistance and durability of the workpiece surface.

Description:

Brown corundum is made of high-quality bauxite, iron scraps, and anthracite by high-temperature melting in an electric arc, crushed and shaped by a mill, magnetically separated to remove iron, and sieved into various particle sizes. It has a dense texture, high hardness, brown color, and high toughness. It is suitable for manufacturing ceramics, resin high-consolidation abrasives, as well as grinding, polishing, sandblasting, precision casting, refractory materials, etc.

Data:

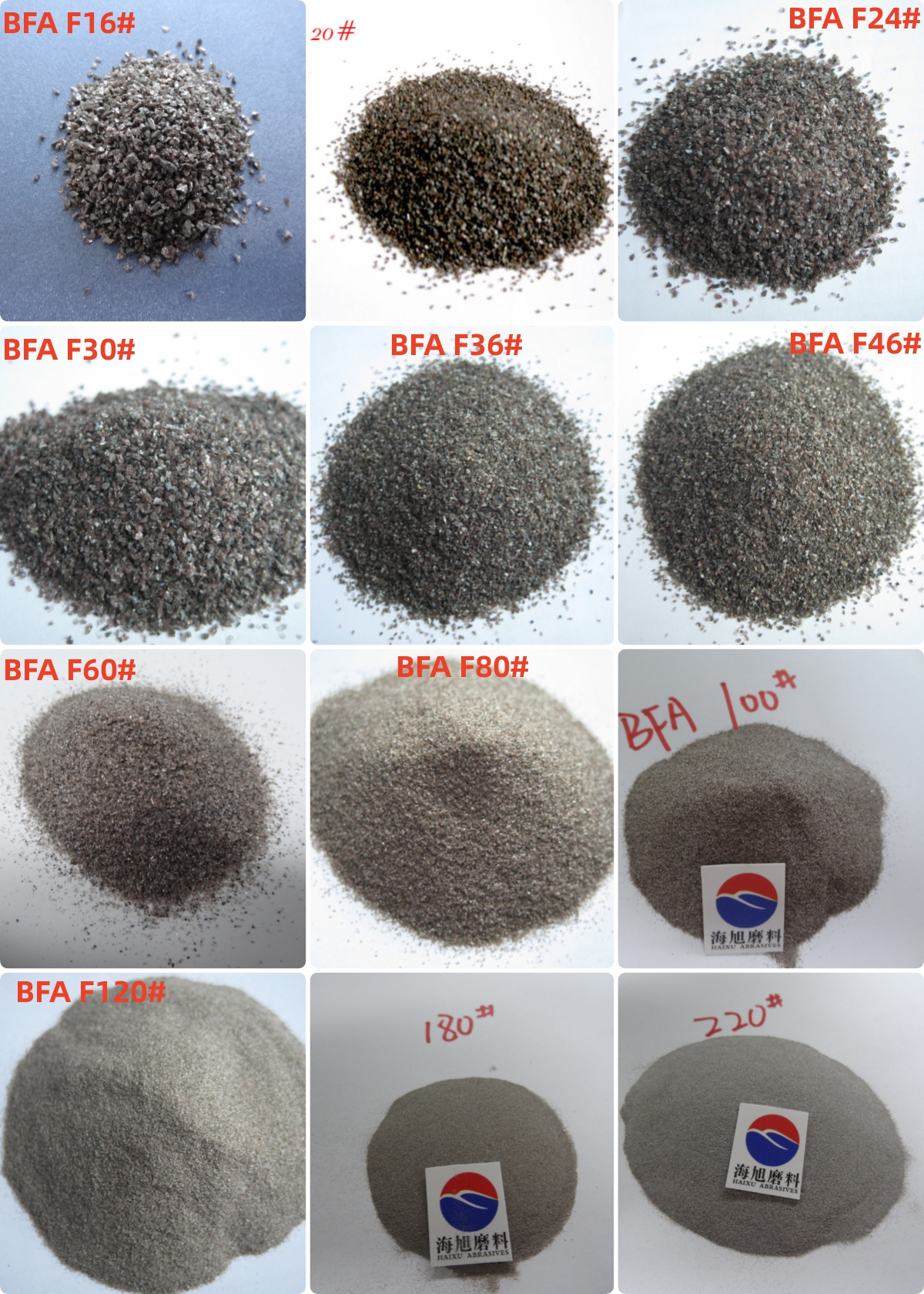

Sizes: | F8, F10, F12, F14, F16, F20, F22, F24, F30, F36, F40, F46, F54, F60, F70, F80, F90, F100, F120, F150, F180, F220# | |||||

Chemcial index | ||||||

Size | Al2O3 | TiO2 | Fe2O3 | SiO2 | ||

F46# | ≥95% | ≤3% | ≤0.5% | ≤1.5% | ||

Physical index | ||||||

Bulk density | Volume density | Mohs Hardness | ||||

1.75-1.95g/cm3 | 3.6-3.9g/cm3 min | 9 | ||||

Brown corundum:

Package: