Brown fused alumina grit

Application of Brown fused alumina grit:

- Production of a broad range of abrasive tools, e.g. grinding wheels, abrasive segments, etc. that are designed for

- Processing durable articles, above all for steel processing,

- Production of abrasive papers and clothes,

- In fireproof and ceramic industry,

- In sand-blast processing.

| Chemical & Physical Properties |

| Crystal Form | Alpha alumina trigonal system |

| Chemical nature | Amphoteric |

| Reaction with acids | Subject to mild attack by aqua and hydrofluoric acid |

| Reaction with Alkalies | Very slight with strong hot solution only |

| Oxidation-reduction effects | None |

| True Density(g/cm3) | 3.97 |

| Hardness | Knoop(kg/cm2) | 2000-2200 |

| Moh’s | 9 |

| Colour | Dark Brown |

| Colour after firing | Light blue |

| Melting point | 2000°C |

| Max Usable temperature | 1900°C |

| Specific heat (cal/g.°C) | 0.26(20-29°C) |

| Coefficient of thermal conductivity | Room temperature | 900°C |

| (cal/cm2.sec.°C) | 0.047 | 0.013 |

| Electrical resistivity (Wcm) | 30°C | 300°C | 900°C | 1600°C |

| 1016 | 1013 | 105 | 104 |

| Coefficient of linear expansion (x10-6) | 7-9(0-1600°C) |

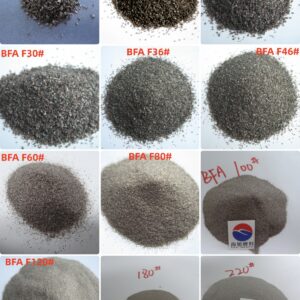

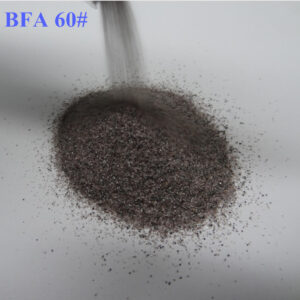

| Available grain sizes |

| Grit No. | Micron | Grit No. | Micron | Grit No. | Micron |

| 10 | 2360 ~ 2000 | 30 | 710 ~ 600 | 80 | 212 ~ 180 |

| 12 | 2000 ~ 1700 | 36 | 600 ~ 500 | 90 | 180 ~ 150 |

| 14 | 1700 ~ 1400 | 40 | 500 ~ 425 | 100 | 150 ~ 125 |

| 16 | 1400 ~ 1180 | 46 | 425 ~ 355 | 120 | 125 ~ 106 |

| 20 | 1180 ~ 1000 | 54 | 355 ~ 300 | 150 | 106 ~ 75 |

| 22 | 1000 ~ 850 | 60 | 300 ~ 250 | 180 | 90 ~ 63 |

| 24 | 850 ~ 710 | 70 | 250 ~ 212 | 220 | 75 ~ 53 |

| Available micron powder sizes |

| China GB 2477-83 | JIS | FEPA(84) / DIN(70) | ISO(77) |

| Grit No. | Standard size range(µm) | Grit No. | ds50 value (µm) | Grit No. | ds50 value (µm) | Grit No. | ds50 value (µm) |

| W63 | 63 – 50 | 240 | 60.0±4.0 | F230/53 | 53±3.0 | 50.0±3.0 | P240 | 58.5±2.0 |

| W50 | 50 – 40 | 280 | 52.0±3.0 | F240/45 | 44.5±2.0 | 42.0±2.0 | P280 | 52.2±2.0 |

| W40 | 40 – 28 | 320 | 46.0±2.5 | F280/37 | 36.5±1.5 | 34.5±1.5 | P320 | 46.2±1.5 |

| W28 | 38 – 20 | 360 | 40.0±2.0 | F320/29 | 29.2±1.5 | 27.7±1.5 | P360 | 40.5±1.5 |

| W20 | 20 – 14 | 400 | 34.0±2.0 | F360/23 | 22.8±1.5 | 21.6±1.5 | P400 | 35.0±1.5 |

| W14 | 10-14 | 500 | 28.0±2.0 | F400/17 | 17.3±1.0 | 16.5±1.0 | P500 | 30.2±1.5 |

| W10 | 10-7 | 600 | 24.0±1.5 | F500/13 | 12.8±1.0 | 12.3±1.0 | P600 | 25.8±1.0 |

| W7 | 7-5 | 700 | 21.0±1.3 | F600/9 | 9.3±1.0 | 9.0±1.0 | P800 | 21.8±1.0 |

| W5 | 5 – 3.5 | 800 | 18.0±1.0 | F800/7 | 6.5±1.0 | 6.3±1.0 | P1000 | 18.3±1.0 |

| – | 1000 | 15.5±1.0 | F1000/5 | 4.5±0.8 | 4.5±0.8 | P1200 | 15.3±1.0 |

| 1200 | 13.0±1.0 | F1200/3 | 3.1±0.5 | 3.1±0.5 | – |

| 1500 | 10.5±1.0 | – |

| 2000 | 8.5±0.7 |

| 2500 | 7.0±0.7 |

| 3000 | 5.7±0.5 |

| For general purposes | For general purposes | For bonded abrasives | For coated abrasives |