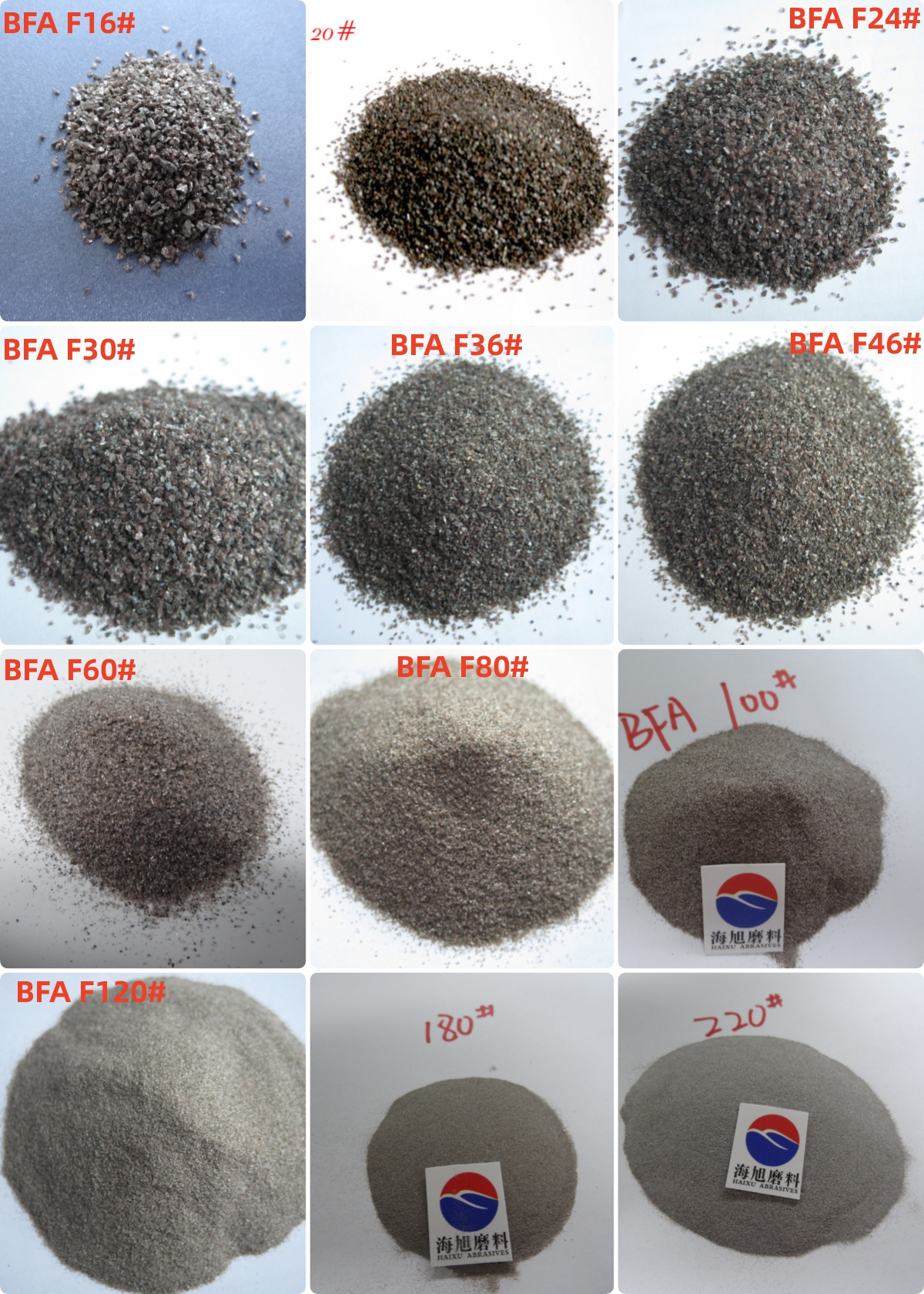

A Grade Brown Fused Alumina Sand

Description for brown fused alumina sand:

Brown fused alumina is produced by melting high-quality bauxite, iron filings, and anthracite in an electric arc furnace at high temperatures 2200℃. The material is then crushed, shaped in a self-grinding machine, iron is removed by magnetic separation, and it is screened into various sizes. The main chemical component is Al2O3, with a content of 94%-96%, along with small amounts of Fe, Si, and Ti. It has a dense texture, high hardness, and is brown in color with great toughness. Brown fused alumina is suitable for manufacturing ceramic and resin high-bond abrasives, as well as for grinding, polishing, sandblasting, precision casting, and refractory materials.

Typical Physical Properties:

| Color | Brown |

| Cyrstal Form | Trigonal system |

| Specific Gravity | 3.95 |

| Bulk Density | 1.53-1.99g/cm3 |

| Mohs Hardness | ≥9 |

| Melting Point | 2200℃ |

| Maximum Use Temperature | 1850℃ |

| True Density | ≥3.60g/cm3 |

Typical Chemical Analysis for brown fused alumina sand:

| Applications | Standard Sizes | Chemical Composition (%) | Magnetic Content (%) | ||||

| Al2O3 | Fe2O3 | SiO2 | TiO2 | ||||

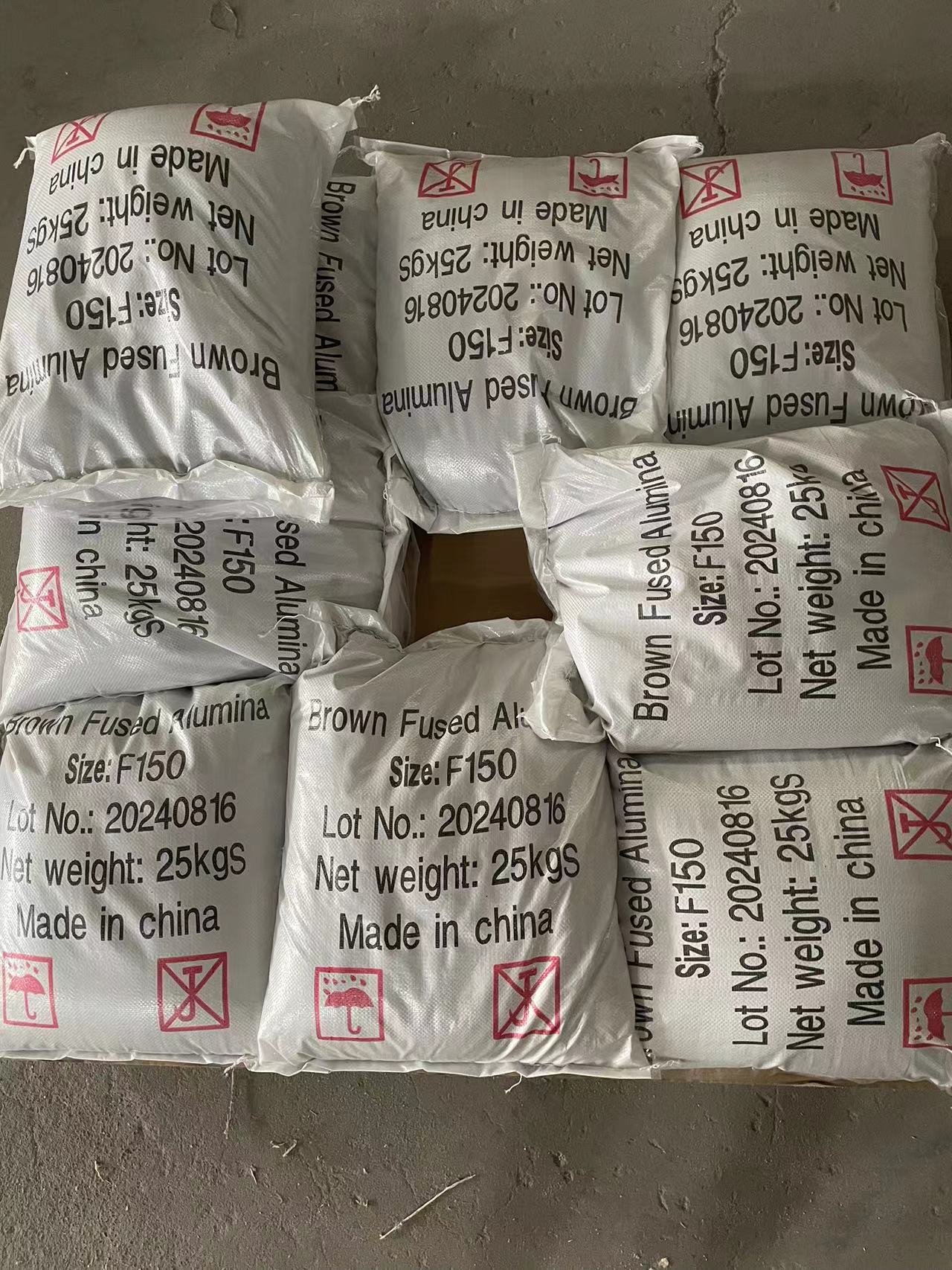

| Abrasives | F | 8#-80# | ≥95 | ≤0.5 | ≤1.5 | ≤3.0 | ≤0.05 |

| 90#-150# | ≥94 | ≤0.03 | |||||

| 180#-240# | ≥93 | ≤1 | ≤2 | ≤4 | ≤0.02 | ||

| P | 8#-80# | ≥95 | ≤0.5 | ≤1.5 | ≤3.0 | ≤0.05 | |

| 100#-150# | ≥94 | ≤0.03 | |||||

| 180#-220# | ≥93 | ≤1 | ≤2 | ≤4 | ≤0.02 | ||

| P280-P800 | ≥92 | ≤0.5 | ≤1.8 | ≤4.0 | – | ||

| W | W63-W7 | ≥92 | ≤0.5 | ≤1.8 | ≤4.0 | ||

| Refractories | Fraction | 0-1mm 1-3mm 3-5mm 5-8mm | ≥95 | ≤0.5 | ≤1.5 | ≤3.0 | – |

| Fine Powder | 200-0 320-0 | ≥92.0 | ≤1 | ≤2 | ≤4 | – | |