Brown fused alumina powder for polishing

Product description for brown fused alumina powder:

Brown fused alumina powder is made of bauxite/anthracite coal, and smelted in electric-arc furnace of high temperature more than 2000 degrees. Abrasives tools made by brown fused alumina are suitable for metal with high tensile(like: steel, malleable iron, bronze etc). Suitable for product high consolidation abrasive, and suitable for grinding, polishing, blasting, precision casting etc. brown fused alumina is also used for refractory material. Brown fused alumina with characteristics like: high purity, good crystalline liquidity, low coefficient of linear expansion, corrosion resistance, high temperature, high strength.

Physical Characteristics:

| Crystal Form: | Alpha-Alumina |

| True Density: | 3.95 g/cm3 |

| Hardness: | Mohs 9.0 |

| Melting Point: | 2000°C |

| Colour: | Brown – Tan |

Sizing Test Methods:

| Sizing: | FEPA Standard 42-2: 2006 |

| JIS R 6001 – 1998 | |

| Micron sizes based on Coulter Multisizer |

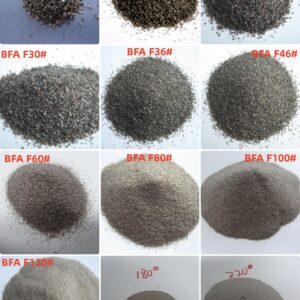

FEPA F – JIS – GB – ISO Standard – Powders/Micro grits:

| Available micron powder sizes | ||||||||

| China GB 2477-83 | JIS | FEPA(84) / DIN(70) | ISO(77) | |||||

| Grit No. | Standard size range(µm) | Grit No. | ds50 value (µm) | Grit No. | ds50 value (µm) | Grit No. | ds50 value (µm) | |

| W63 | 63 – 50 | 240 | 60.0±4.0 | F230/53 | 53±3.0 | 50.0±3.0 | P240 | 58.5±2.0 |

| W50 | 50 – 40 | 280 | 52.0±3.0 | F240/45 | 44.5±2.0 | 42.0±2.0 | P280 | 52.2±2.0 |

| W40 | 40 – 28 | 320 | 46.0±2.5 | F280/37 | 36.5±1.5 | 34.5±1.5 | P320 | 46.2±1.5 |

| W28 | 38 – 20 | 360 | 40.0±2.0 | F320/29 | 29.2±1.5 | 27.7±1.5 | P360 | 40.5±1.5 |

| W20 | 20 – 14 | 400 | 34.0±2.0 | F360/23 | 22.8±1.5 | 21.6±1.5 | P400 | 35.0±1.5 |

| W14 | 10-14 | 500 | 28.0±2.0 | F400/17 | 17.3±1.0 | 16.5±1.0 | P500 | 30.2±1.5 |

| W10 | 10-7 | 600 | 24.0±1.5 | F500/13 | 12.8±1.0 | 12.3±1.0 | P600 | 25.8±1.0 |

| W7 | 7-5 | 700 | 21.0±1.3 | F600/9 | 9.3±1.0 | 9.0±1.0 | P800 | 21.8±1.0 |

| W5 | 5 – 3.5 | 800 | 18.0±1.0 | F800/7 | 6.5±1.0 | 6.3±1.0 | P1000 | 18.3±1.0 |

| – | 1000 | 15.5±1.0 | F1000/5 | 4.5±0.8 | 4.5±0.8 | P1200 | 15.3±1.0 | |

| 1200 | 13.0±1.0 | F1200/3 | 3.1±0.5 | 3.1±0.5 | – | |||

| 1500 | 10.5±1.0 | – | ||||||

| 2000 | 8.5±0.7 | |||||||

| 2500 | 7.0±0.7 | |||||||

| 3000 | 5.7±0.5 | |||||||

| For general purposes | For general purposes | For bonded abrasives | For coated abrasives | |||||